|

Over the last few months, we have been working on launching Asteria, a new brand in the tea lifestyle space. We put together a small team and started working on designing and building both a brand and our first product, Explorer 1.0. When building the brand, we played with colors, built prototypes, and dealt with manufacturing. We had fun, got into stressful times, and learned a lot. Here are three little random lessons we’ll keep in mind. 1- Prototype, Talk to People, but Don’t Expect them to Do Your JobFirst, let us clarify that virtual prototypes of pictures and 3D models are great. However, they are by no means a replacement for physical prototypes. Strive to end up with physical prototypes and have other people outside your team interact with them. Then, observe, and get feedback from those people. This is all obvious, right? Here are the little things to watch out for:

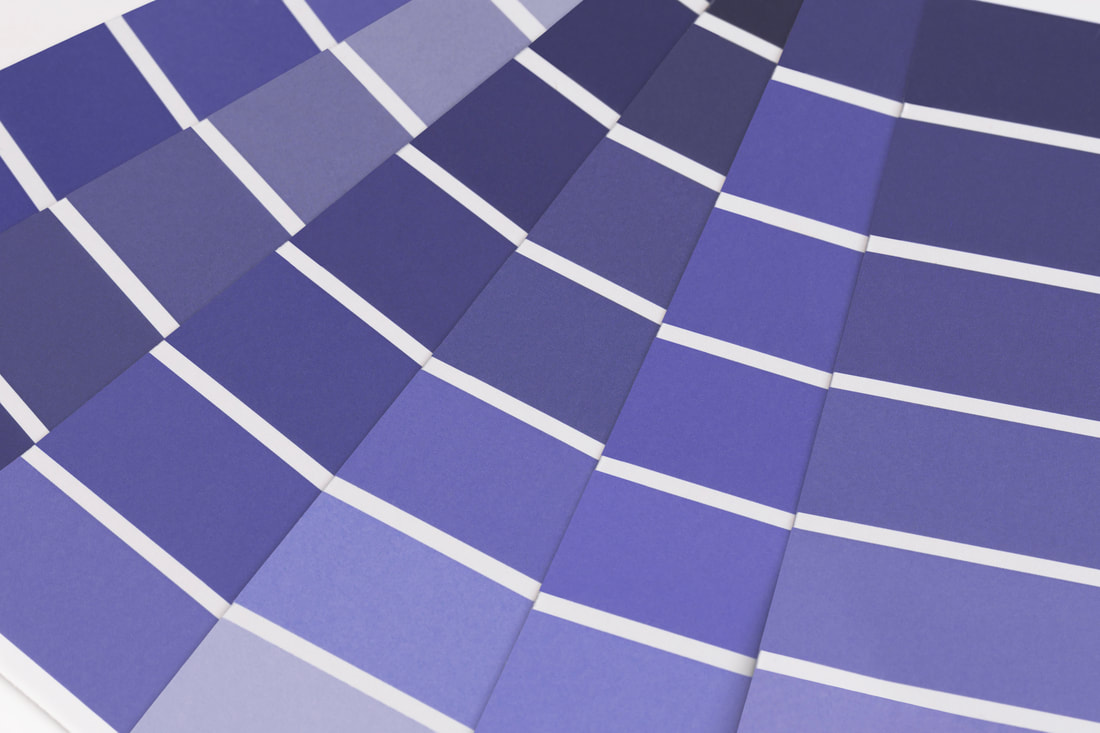

During those interactions, know their duty and your job. Their duty is to provide personal insights from their perspectives and situations. They are not there to suggest solutions to the problems you are trying to solve, that’s your job. 2- Colors and Coloring StandardsThis one might be a little obvious to some, a little hidden to others. When building a brand that might end with physical products, you’ll need to pick your coloring system carefully, especially if you are keen on keeping consistent branding. There are multiple coloring systems out there. Let’s go over some major ones:

CMYK and Pantone have less variety of colors but are more viable for the physical world. So, a good approach is to start there. You will most likely be able to find identical colors in HEX and RBG after. Also, pick your brand colors out of official colors prints, not screens. The colors might already look slightly different when dealing with different printers/ printing service providers. Those differences might be because of the product’s materials or the different machines/techniques used to do the coloring. However, you don’t want to be subjected to more variance because one manufacturer has less flexibility than another due to your coloring codes. Suppose you use the HEX system to choose your brand colors. In that case, there is a higher likelihood that you will not be able to replicate the exact color of physical objects. 3- Work with Your ManufacturersKnowing how things are made from a manufacturing perspective is a good idea. However, even with that knowledge, always ask for your manufacturer’s opinions. Your success of the manufacturer’s best interest as this means you will be more likely to return for more of their service. This is not to mention that they have a reputation to protect. Many people overestimate the knowledge they need to have to communicate with manufacturers. In reality, most manufacturers don’t expect you to be an expert in their fields, which is why they often have engineers to help you manufacture your design. This includes suggesting ways to make your design more manufacturable. Different manufacturers are often specialized in one or two things. For example, a box manufacturer will likely be able to work from the box sketches you have on a napkin because that’s all they do. A prototyping facility that does 3D printing would tell you the parts of your design that are not possible to make and likely provide some recommendations to tackle those issues. Again, it is helpful if you know how manufacturing works so you can save tons of valuable design time, but keep in mind that manufacturers are often there to help. Also, always contact more than one manufacturer, check on different qualities and compare the different customer support, qualities, and prices you can get. If you have the time and money, get a manufacturing prototype for your final designs well. Here you have it, those are three random little lessons we got to learn more of in our journey to build Asteria. Would you like us to share more practical lessons? Let me know in the comment below. Also, don’t forget to share your experiences and things to watch out for when designing a new product. If you would like us to share the whole Asteria building experience, let us know in the comments. Finally, if you are looking for help to build your own brand, drop us a line. We are here to help. By Tayseer AlmattarTayseer is a passionate designer and educator. He believes that innovation potential can be grown and natured within organizations with relevant design innovation processes.

LinkedIn: https://www.linkedin.com/in/tayseer-almattar-design-innovation

0 Comments

Leave a Reply. |

AuthorThe following blogs are written by TforDesign team and community members. Categories

All

|

© 2013 - 2024 TforDesign. All rights reserved.

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

RSS Feed

RSS Feed