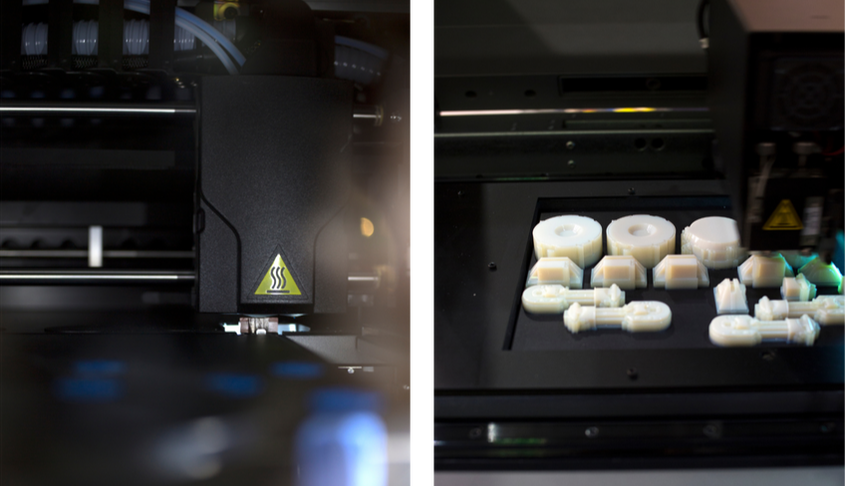

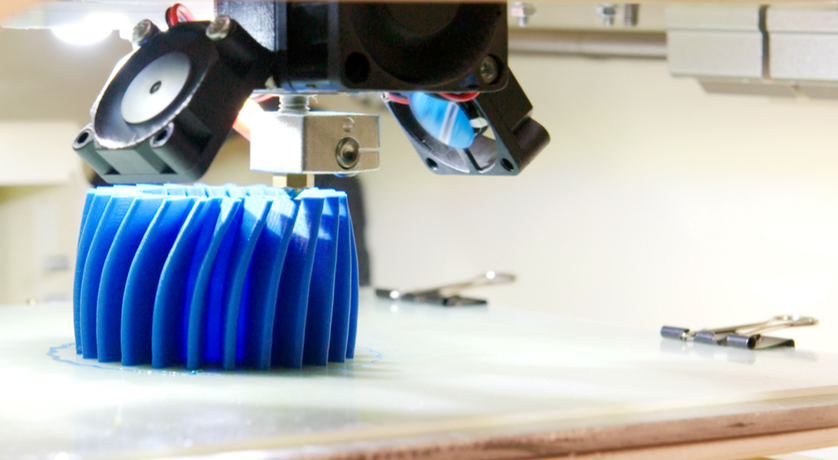

Let's start with an intro3D printing is the process of creating a three-dimensional object from a digital file. It works by melting or solidifying plastic or other materials and laying down successive layers to create an object. 3D printing has become one of the most popular technologies in product design today, with more and more designers using it for everything from concept models to final prototype production. This article explores how 3D printing can work for your design workflow and some of the challenges you might face along the way. What is 3D printing?3D printing is a process of making three-dimensional solid objects from a digital file. 3D printing or additive manufacturing (AM) technology has been around since the 1980s. Since then, the 3D printing market size has been growing while adding lots of value to many businesses. However, it only recently became affordable for home and business use. 3D printing is also known as Additive Manufacturing (AM) or Rapid Prototyping. An AM machine can print an object by building it up in layers based on the design you created in your CAD program, often using plastic materials that are melted and then cooled to create the final product. The 3D printer builds up each layer by adding material until the object is complete. Product design workflow with 3D printing3D printing is a tool, not a solution. It’s important to remember that 3D printing is just one component of product design, and it will never be able to solve every problem in your workflow. 3D printing can help you:

Benefits of 3D printing in product design3D printing offers a number of benefits in product design.

Challenges of 3D printing in product designDespite the hype, 3D printing is not a cure-all for all design problems. In fact, it is often not an appropriate solution for even the most fundamental aspects of product design.

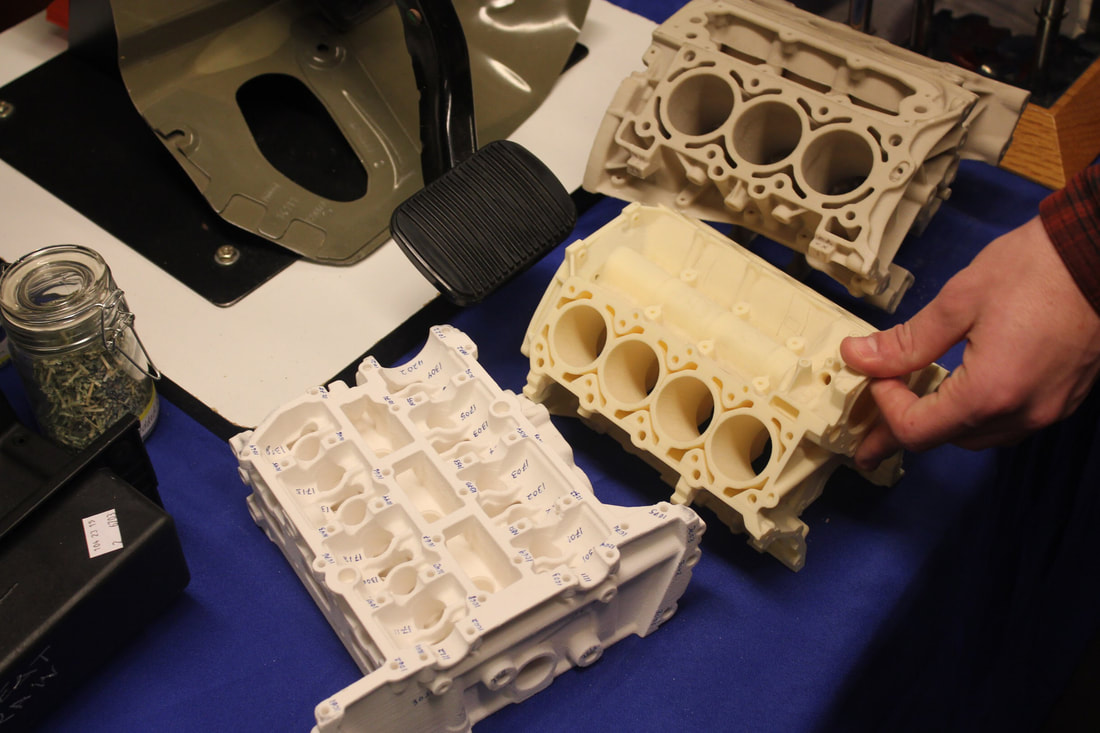

Role of 3D printing in the product development process3D printing is an important technology in the product development process. Because of its speed, accuracy, and affordability, 3D printing is used at any stage of the design process. Design teams use 3D printing to validate ideas and concepts early on in the design process. This saves time and money by helping designers avoid costly rework later on in the development cycle. The first stage where 3D printing can be applied is during initial prototyping. Prototypes are often printed as fast as possible so that they can be evaluated by users or other stakeholders as soon as possible. These prototypes are typically not intended for mass production but rather serve as a proof of concept or idea validation tool that helps designers decide if their current direction is heading towards something worth pursuing further. The benefit of using 3D printing technologies is that they allow you to produce multiple iterations quickly without having to wait for molds or tooling, which often takes months before being produced in metal or plastic components! Product designers are using more and more advanced technologies to develop innovative products for the global market.3D printing is a fast and efficient process. Designers can create, prototype, and test their products in as little as a day. This technology has been used to produce everything from intricate medical devices to custom-made shoes for astronauts on the International Space Station. Product designers often use 3D printing to create prototypes of new products or make small changes to existing ones. Prototypes help them test the functionality of their designs before they go into full production, which saves time and money because there is no need for large-scale manufacturing until the design is finalized. 3D printing also allows companies to design unique items that aren't available through traditional manufacturing methods, such as injection molding or casting (the process by which metal or plastic parts are created by pouring liquid material into a mold). Let's wrap up!3D printing is becoming more and more popular as a tool for product design. In this article, we discussed the benefits of using 3D printing in product design and outlined some of the challenges that designers face when using this technology for their projects. We also talked about how 3D printing can help designers create prototypes faster than ever before!

Now that you have an idea of the great value 3D printing can bring you, you should consider diving deeper into exploring what the technology is all about and exploring all the values it can bring you. Luckily, we have a comprehensive program made just for that: 3D Printing Opportunities and Applications. Make sure to check it out, we are looking forward to seeing you there.

2 Comments

"Interesting" is the word we often hear when telling others about our innovative ideas. Unfortunately, this is mostly the last thing we hear about it before it soon dissolves in the busyness of both working and personal lives. Unless formed, shaped, and colored, ideas by themselves are defenseless and mostly worthless. How can an idea be more than just "interesting"? Unless formed, shaped, and colored, ideas by themselves are defenseless and mostly worthless. One way to get past the "interesting" point and get more attention is to make your audience 'feel' the idea. This is guaranteed to give you more of their attention for a longer time. Prototyping is the best way to have your audience feel your idea. In a broad sense, a prototype is whatever can give your idea a visible/tangible form and/or feeling. This can be with simple drawings, 3D printed or virtual models, videos, interface mock-ups, etc. Depending on your situation, a prototype does not have to be functional or attractive. However, building a prototype does require more investment and effort than to just speak of the idea. More Reasons for Why Prototyping:Here are some reasons that can partially illustrate the power of prototypes:

Everything is Prototype-able:Prototyping is becoming an essential and central practice working in design innovation. The shapes and forms of the prototypes can be very different depending on the field and purpose of the prototype. The commonality is that everything is prototype-able. For example, a user interface can be prototyped with a series of hand sketches on paper, an interactive dashboard can be prototyped with linked PowerPoint slides, a video advertisement can be prototyped with a cellphone camera, a physical product can be prototyped with 3D printing, etc. With that, it would be worth it to have rapid prototyping as a key part of your innovation processes. In an earlier blog post, we discussed 3D Printing and product design and how prototyping can play an important role in the field. You can also check out the 3D Printing Opportunities and Applications course that dives even deeper into 3D printing for prototyping and other fields. Do you use prototyping to support your ideas? What types of prototypes do you often build, and for what reasons? Share your thoughts in the comments section. By Tayseer Almattar, TforDesign FounderTayseer is the founder of TforDesign. He has a passion for learning design and making all learning digestible and exciting.

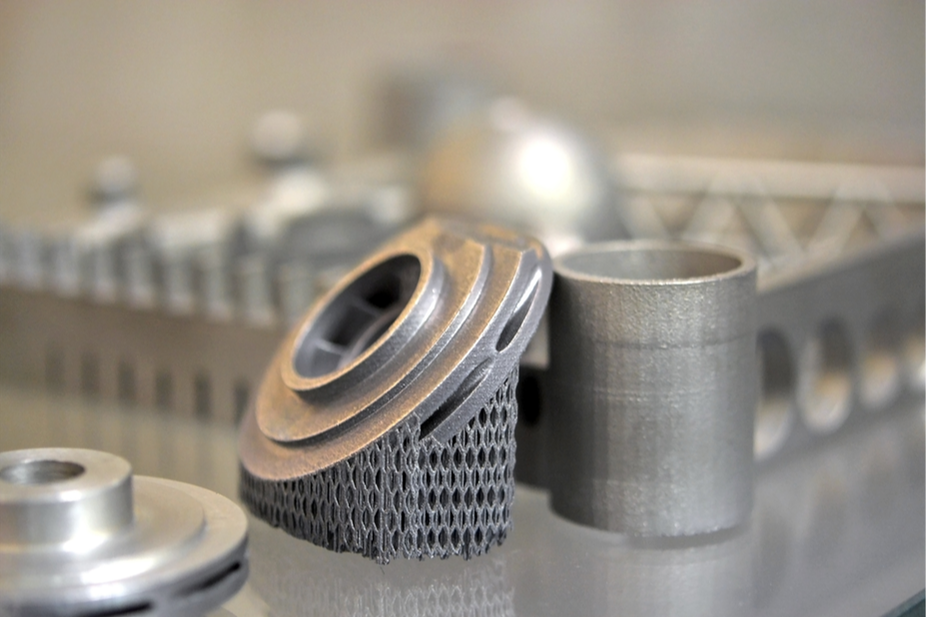

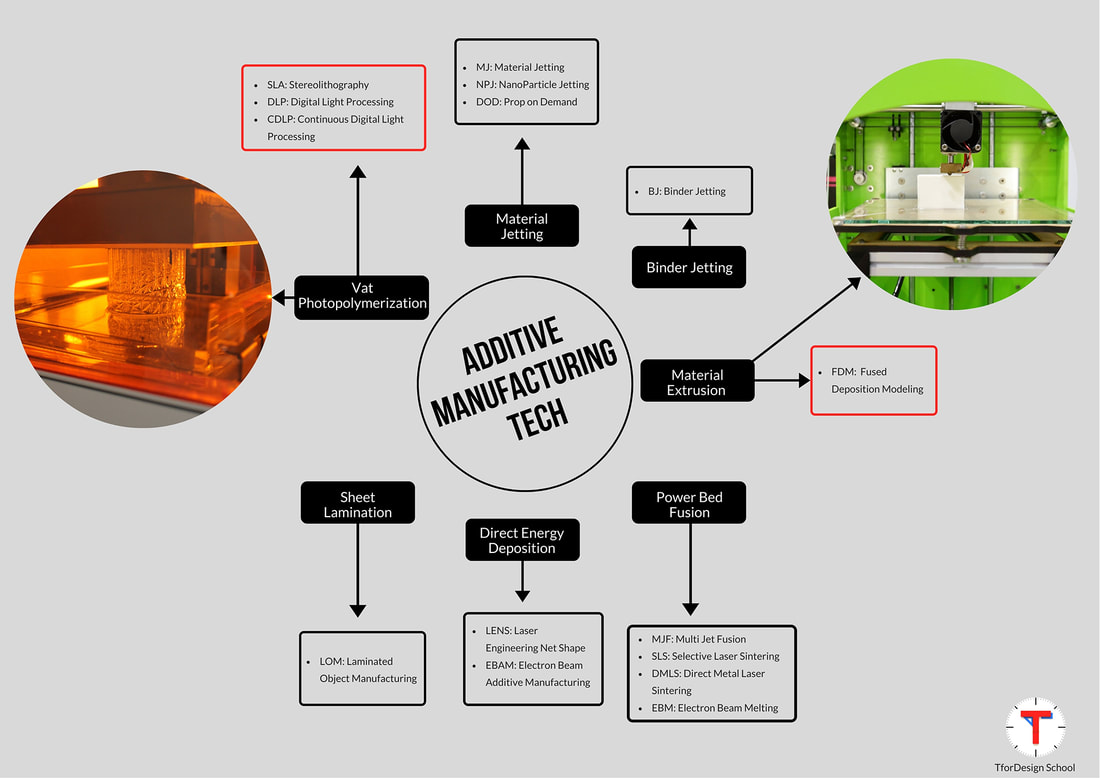

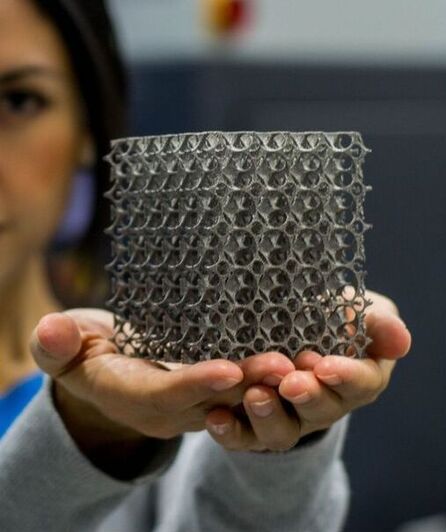

LinkedIn: https://www.linkedin.com/in/tayseer-almattar-design-innovation If I am to guess, you have most definitely heard the term 3D Printing before. So, let us dig deeper into it. 3D Printing falls under the broader term Additive Manufacturing (AM). More specifically, the term 3D Printing is more commonly used to describe entry-level technologies that are low in cost and accessible to the average consumer. Hence, the term became more known to people outside that specific technical sphere. However, for our purposes, we can consider them interchangeable. The term Additive Manufacturing only makes sense when contrasted with its more traditional counterpart Subtractive Manufacturing. In Subtractive Manufacturing, you start with lots of material; then, you remove from it until you reach your final product. For example, you can start with an aluminum block, then use a CNC machine to remove material to get a laptop chassis. Or you can start with sheet metal, then cut and form it to end up with a support bracket. In contrast, in Additive Manufacturing (AM), you would start from an empty canvas, and then start adding materials to end up with your final product. For example, you would start from a blank canvas, then add layers to end up with a laptop chassis, a support bracket, or a turbine blade. About the TechAdditive manufacturing has reached a good level of maturity with a wide variety of technologies. However, most of the technologies are more common for industrial use due to the machines' high cost and the required space, maintenance, and expertise to operate them. However, they mostly work using the same concept by adding layers of materials and solidifying them into a final shape. Materials can range from plastics, metals, paper, wax, sand, and composites. The following picture shows a 3D-printed metal impeller. The technologies that made it to consumer levels are:

The rest have mostly remained confined to industrial use. The following figure highlights the different 3D printing technologies currently available. Pictures and red rectangles are for technologies that are more available at the consumer level. Why use Additive Manufacturing (AM) in Product DesignAs of now, Product Design applications represent the most prominent usage of Additive Manufacturing. This is both in the Product Development Stage as well as the Product Production Stage. Let us talk briefly about those two stages. Product Development Stage:Within the product development stage, AM has three main advantages:

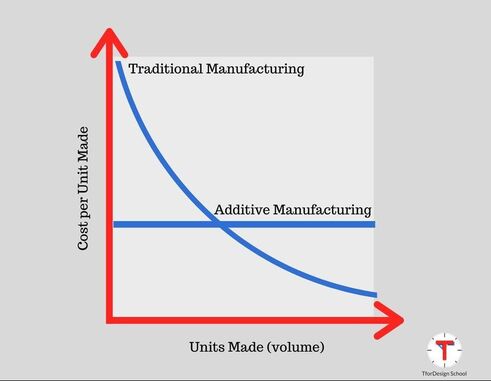

Product Production Stage:The advantages AM brings for the product development cycle are more known and utilized than the Production Stage. In the Product Development stage, AM has two main advantages. Being able to produce custom products and complex geometries. 1. Custom ProductsAM enables you to produce unique, custom products on a small scale. For plastic-based applications, Injection Molding is the traditional counterpart for Additive Manufacturing. Both methods can produce plastic products, but the cost models are very different. The figure below highlights the difference in cost between Additive Manufacturing and Injection Molding. Additive manufacturing has a fixed cost per unit, while injection molding has a variant one that decreases the more you produce a product. This makes additive manufacturing great for creating custom products on a smaller scale. 2. Complex GeometriesAM enables you to produce products that are not possible by traditional methods. This can be especially the case with metal products where the traditional counterpart is Subtractive Manufacturing. Due to its nature, AM technologies can enable the creation of internal structures that are otherwise impossible to make with traditional methods. The figure highlights a part structure that is only possible with Additive Manufacturing. The scope of AM is much wider than what is described in this article. Besides the direct product design applications, AM can bring lots of unique advantages to other technical areas like supply chain and tooling. So, regardless of which area you are working in, you should keep an eye on AM and ways it can support your business. Have you ever used AM/3D Printing before? What did you use it for? Share your experience with us in the comments. Also, what else would you like to know about the world of Additive Manufacturing? If you enjoyed this article, do not forget to share it with your networks. *If you are looking to learn 3D modeling for 3D Printing, check out the TforDesign school, which offers a range of online 3D modeling courses on SOLIDWORKS, portfolio building, and sustainability. By Tayseer Almattar, TforDesign FounderTayseer is the founder of TforDesign. He has a passion for learning design and making all learning digestible and exciting.

LinkedIn:https://www.linkedin.com/in/tayseer-almattar-design-innovation |

AuthorThe following blogs are written by TforDesign team and community members. Categories

All

|

© 2013 - 2024 TforDesign. All rights reserved.

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

RSS Feed

RSS Feed