|

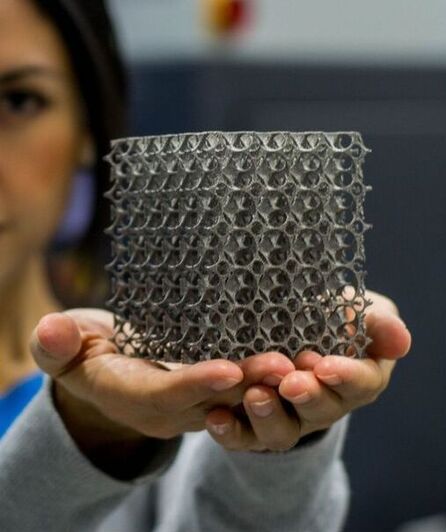

If I am to guess, you have most definitely heard the term 3D Printing before. So, let us dig deeper into it. 3D Printing falls under the broader term Additive Manufacturing (AM). More specifically, the term 3D Printing is more commonly used to describe entry-level technologies that are low in cost and accessible to the average consumer. Hence, the term became more known to people outside that specific technical sphere. However, for our purposes, we can consider them interchangeable. The term Additive Manufacturing only makes sense when contrasted with its more traditional counterpart Subtractive Manufacturing. In Subtractive Manufacturing, you start with lots of material; then, you remove from it until you reach your final product. For example, you can start with an aluminum block, then use a CNC machine to remove material to get a laptop chassis. Or you can start with sheet metal, then cut and form it to end up with a support bracket. In contrast, in Additive Manufacturing (AM), you would start from an empty canvas, and then start adding materials to end up with your final product. For example, you would start from a blank canvas, then add layers to end up with a laptop chassis, a support bracket, or a turbine blade. About the TechAdditive manufacturing has reached a good level of maturity with a wide variety of technologies. However, most of the technologies are more common for industrial use due to the machines' high cost and the required space, maintenance, and expertise to operate them. However, they mostly work using the same concept by adding layers of materials and solidifying them into a final shape. Materials can range from plastics, metals, paper, wax, sand, and composites. The following picture shows a 3D-printed metal impeller. The technologies that made it to consumer levels are:

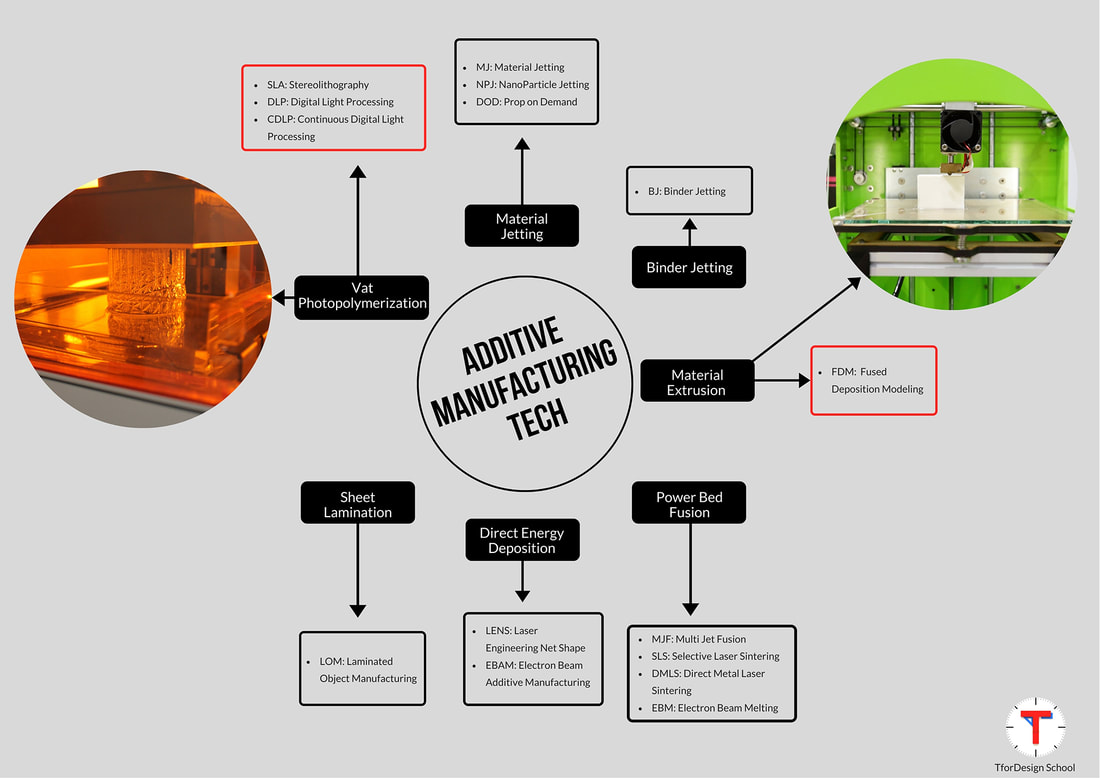

The rest have mostly remained confined to industrial use. The following figure highlights the different 3D printing technologies currently available. Pictures and red rectangles are for technologies that are more available at the consumer level. Why use Additive Manufacturing (AM) in Product DesignAs of now, Product Design applications represent the most prominent usage of Additive Manufacturing. This is both in the Product Development Stage as well as the Product Production Stage. Let us talk briefly about those two stages. Product Development Stage:Within the product development stage, AM has three main advantages:

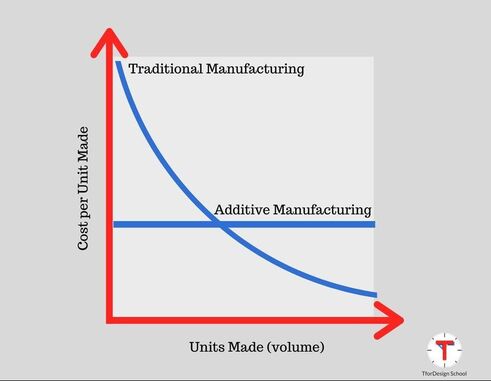

Product Production Stage:The advantages AM brings for the product development cycle are more known and utilized than the Production Stage. In the Product Development stage, AM has two main advantages. Being able to produce custom products and complex geometries. 1. Custom ProductsAM enables you to produce unique, custom products on a small scale. For plastic-based applications, Injection Molding is the traditional counterpart for Additive Manufacturing. Both methods can produce plastic products, but the cost models are very different. The figure below highlights the difference in cost between Additive Manufacturing and Injection Molding. Additive manufacturing has a fixed cost per unit, while injection molding has a variant one that decreases the more you produce a product. This makes additive manufacturing great for creating custom products on a smaller scale. 2. Complex GeometriesAM enables you to produce products that are not possible by traditional methods. This can be especially the case with metal products where the traditional counterpart is Subtractive Manufacturing. Due to its nature, AM technologies can enable the creation of internal structures that are otherwise impossible to make with traditional methods. The figure highlights a part structure that is only possible with Additive Manufacturing. The scope of AM is much wider than what is described in this article. Besides the direct product design applications, AM can bring lots of unique advantages to other technical areas like supply chain and tooling. So, regardless of which area you are working in, you should keep an eye on AM and ways it can support your business. Have you ever used AM/3D Printing before? What did you use it for? Share your experience with us in the comments. Also, what else would you like to know about the world of Additive Manufacturing? If you enjoyed this article, do not forget to share it with your networks. *If you are looking to learn 3D modeling for 3D Printing, check out the TforDesign school, which offers a range of online 3D modeling courses on SOLIDWORKS, portfolio building, and sustainability. By Tayseer Almattar, TforDesign FounderTayseer is the founder of TforDesign. He has a passion for learning design and making all learning digestible and exciting.

LinkedIn:https://www.linkedin.com/in/tayseer-almattar-design-innovation

5 Comments

12/6/2022 11:29:48 pm

If you have any issues with the printer installation or any other issues with the printer and computer, I have provided a solution. Please go to adnantech.com to see my website.

Reply

2/2/2023 03:29:02 am

You are absolutely correct and thanks for giving information about 3d printing and product design. I loved your blog and thanks for publishing this!! I am really happy to come across this exceptionally well-written content. Thanks for sharing and look for more in future!!

Reply

6/8/2023 04:35:16 am

Ts a great pleasure reading your post.we provide.High-Speed, Low-Cost T-Shirt Printing in Singapore.<a href="https://luminousprinting.com.sg/">T shirt printing singapore</a>

Reply

7/12/2024 10:22:55 pm

Great article! You've done a fantastic job of outlining the core benefits of Additive Manufacturing (AM) in product design. The clear comparison between AM and subtractive manufacturing, along with the visual aids, makes the concepts easily understandable.

Reply

Leave a Reply. |

AuthorThe following blogs are written by TforDesign team and community members. Categories

All

|

© 2013 - 2024 TforDesign. All rights reserved.

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

RSS Feed

RSS Feed