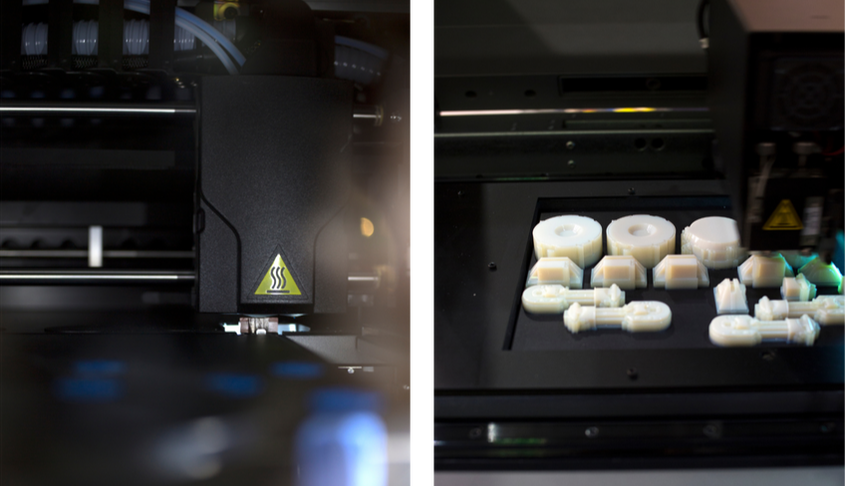

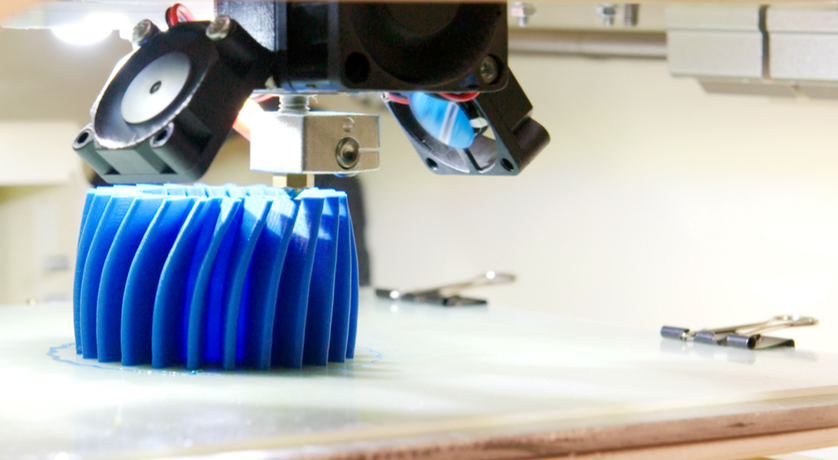

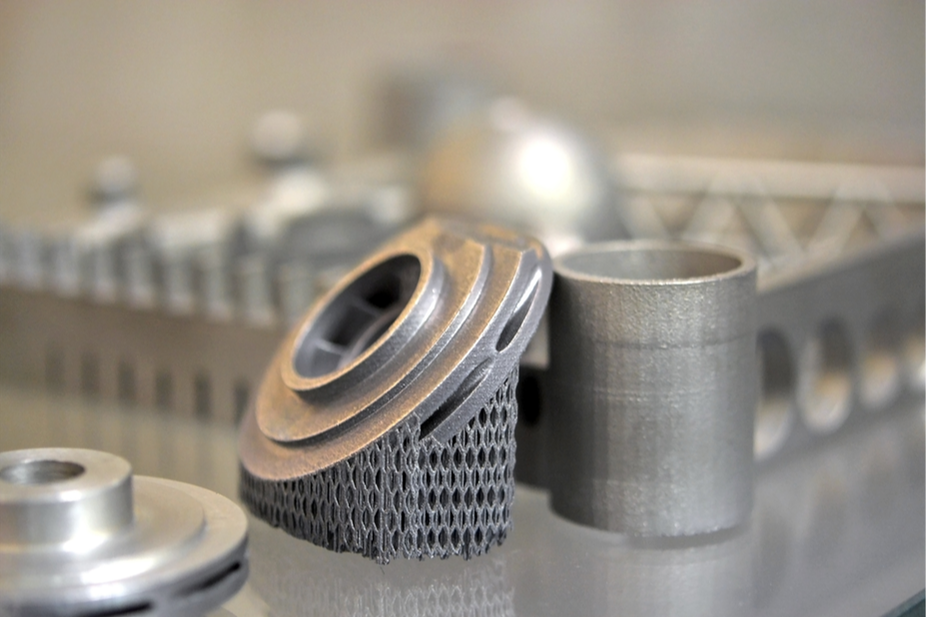

Let's start with an intro3D printing is the process of creating a three-dimensional object from a digital file. It works by melting or solidifying plastic or other materials and laying down successive layers to create an object. 3D printing has become one of the most popular technologies in product design today, with more and more designers using it for everything from concept models to final prototype production. This article explores how 3D printing can work for your design workflow and some of the challenges you might face along the way. What is 3D printing?3D printing is a process of making three-dimensional solid objects from a digital file. 3D printing or additive manufacturing (AM) technology has been around since the 1980s. Since then, the 3D printing market size has been growing while adding lots of value to many businesses. However, it only recently became affordable for home and business use. 3D printing is also known as Additive Manufacturing (AM) or Rapid Prototyping. An AM machine can print an object by building it up in layers based on the design you created in your CAD program, often using plastic materials that are melted and then cooled to create the final product. The 3D printer builds up each layer by adding material until the object is complete. Product design workflow with 3D printing3D printing is a tool, not a solution. It’s important to remember that 3D printing is just one component of product design, and it will never be able to solve every problem in your workflow. 3D printing can help you:

Benefits of 3D printing in product design3D printing offers a number of benefits in product design.

Challenges of 3D printing in product designDespite the hype, 3D printing is not a cure-all for all design problems. In fact, it is often not an appropriate solution for even the most fundamental aspects of product design.

Role of 3D printing in the product development process3D printing is an important technology in the product development process. Because of its speed, accuracy, and affordability, 3D printing is used at any stage of the design process. Design teams use 3D printing to validate ideas and concepts early on in the design process. This saves time and money by helping designers avoid costly rework later on in the development cycle. The first stage where 3D printing can be applied is during initial prototyping. Prototypes are often printed as fast as possible so that they can be evaluated by users or other stakeholders as soon as possible. These prototypes are typically not intended for mass production but rather serve as a proof of concept or idea validation tool that helps designers decide if their current direction is heading towards something worth pursuing further. The benefit of using 3D printing technologies is that they allow you to produce multiple iterations quickly without having to wait for molds or tooling, which often takes months before being produced in metal or plastic components! Product designers are using more and more advanced technologies to develop innovative products for the global market.3D printing is a fast and efficient process. Designers can create, prototype, and test their products in as little as a day. This technology has been used to produce everything from intricate medical devices to custom-made shoes for astronauts on the International Space Station. Product designers often use 3D printing to create prototypes of new products or make small changes to existing ones. Prototypes help them test the functionality of their designs before they go into full production, which saves time and money because there is no need for large-scale manufacturing until the design is finalized. 3D printing also allows companies to design unique items that aren't available through traditional manufacturing methods, such as injection molding or casting (the process by which metal or plastic parts are created by pouring liquid material into a mold). Let's wrap up!3D printing is becoming more and more popular as a tool for product design. In this article, we discussed the benefits of using 3D printing in product design and outlined some of the challenges that designers face when using this technology for their projects. We also talked about how 3D printing can help designers create prototypes faster than ever before!

Now that you have an idea of the great value 3D printing can bring you, you should consider diving deeper into exploring what the technology is all about and exploring all the values it can bring you. Luckily, we have a comprehensive program made just for that: 3D Printing Opportunities and Applications. Make sure to check it out, we are looking forward to seeing you there.

2 Comments

2/13/2023 01:32:24 pm

The other day, I spoke with my cousin about his current research project, and he told me that he's interested in creating a prototype to show to potential investors. That's why I think he'd benefit from reading your information on 3D printing and how it's a fast and efficient process to create and test products. I appreciate your intake on 3D printers and how their technology is helping industries evolve.

Reply

Leave a Reply. |

AuthorThe following blogs are written by TforDesign team and community members. Categories

All

|

© 2013 - 2024 TforDesign. All rights reserved.

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

RSS Feed

RSS Feed