|

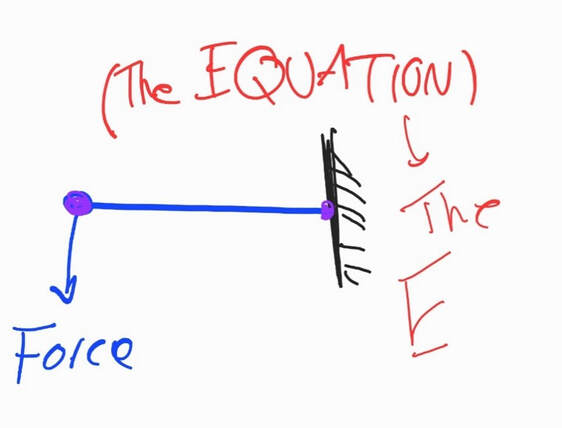

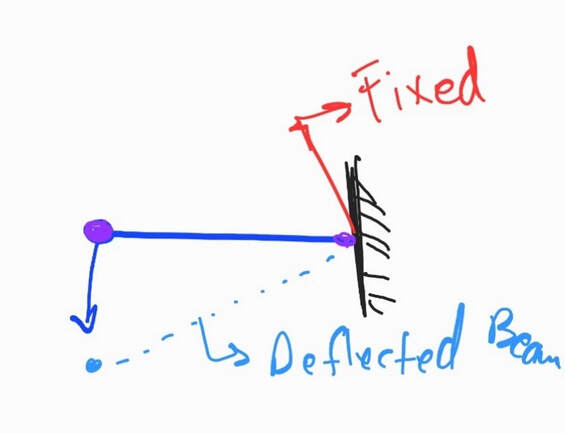

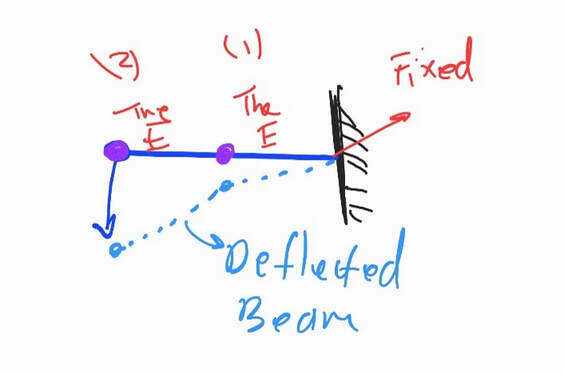

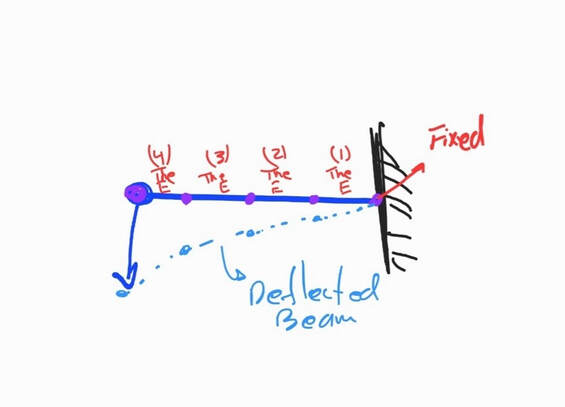

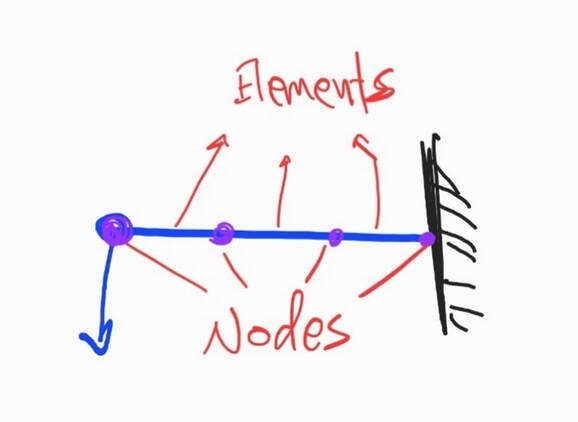

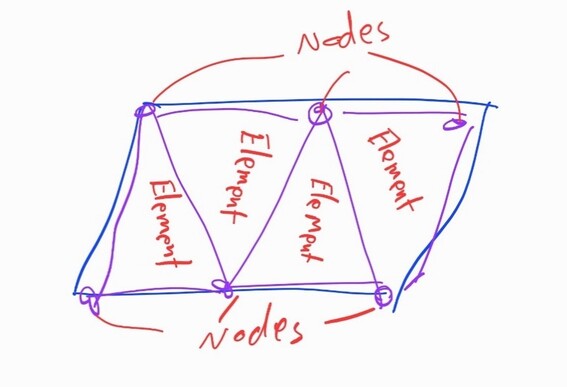

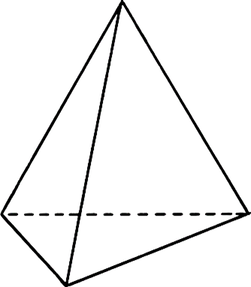

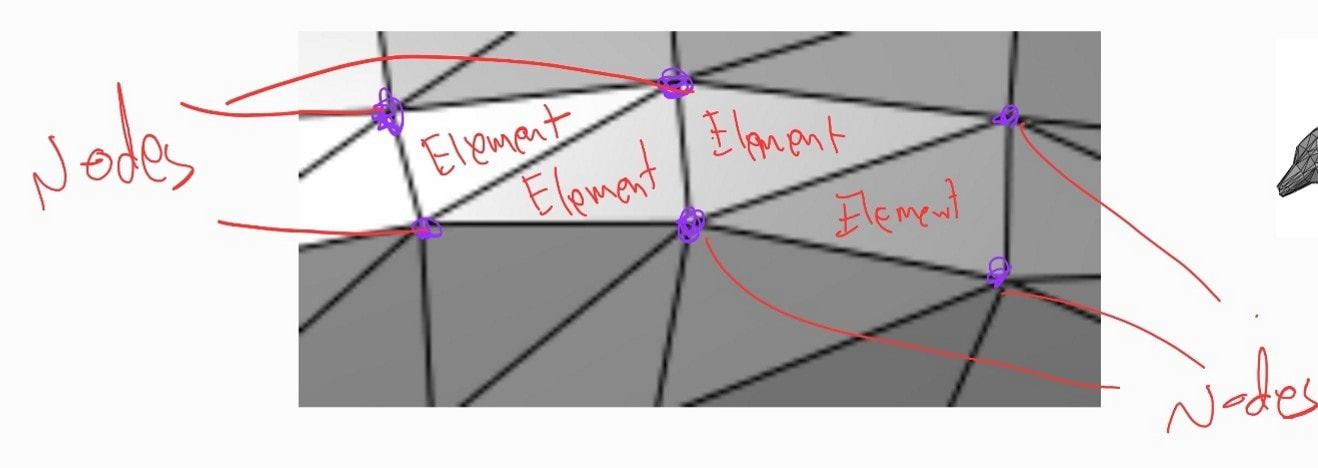

In this post, we will try to make sense of what is finite element analysis (FEA) and how it works without getting into talking about equations or much technical terms. SOLIDWORKS Simulation (and other software) uses FEA to solve designs. Thus, knowing a bit of background about FEA will help us understand many of the settings to optimize our results. To explain FEA in simple terms, we can try simplifying FEA with a story of the progression of the elements from one dimension to 3 dimensions. One Dimensional Beams:It all started with the classic problem of a beam. The beam is fixed on a wall from one end, and there is a force on the other end. Experts came together and made up an equation to find the deflection at the outer end. What the equation looked like is none of our concern for now, so we can just call it THE EQUATION. Here is what concerns us: To be able to calculate the deflection on the outer end, we had to know beforehand what the deflection is on the inner end connected to the wall. In this classic beam case, we know that the inner end is fixed to a wall. Thus, there is no deflection, or the deflection is zero. With that known to us, we can apply the equation and find the deflection. Now the question is: What if we want to know the deflection in the middle of the beam? To find this, we can split the beam into two and redo the whole calculation. We can start with the first half, in one end we know the deflection is zero, so we can apply THE EQUATION to find the deflection at the end of the first half. Then, we can move to the second half and apply the same equation. Again, we already know the deflection in one end because we just calculated It, then the equation will give us the other end. Finite Element Analysis is dividing a structure into a smaller, finite number of elements which we can analyze one by one, then putting all those elements together gives us an understanding of the whole structure. What if we want to know the deflection in every quarter of the beam? In this case, we can simply redo the same procedure the same way, splitting the beam into four parts. We can go the same approach every tenth of the beam, every twentieth, and so on. Now let us stop here for a second to name things, we can all those little beam divisions: ELEMENTS,, at the end of each element, there are points that we can call NODES. This approach we just used or described in analyzing our beam is Finite Element Analysis. It is dividing a structure into a smaller, finite number of elements which we can analyze one by one, then putting all those elements together gives us an understanding of the whole structure. Two Dimensional Shells / Surfaces:Just now, we were looking at a straight beam, which we were able to split into straight little elements of lines and nodes. The next step would be to go to two dimensions. We can call those shells or sheets. A shell is anything that is relatively thin and of uniform thickness. Those include the common structures of sheet metals. Sheet metals can take many different shapes and forms. Also, unlike one-dimensional beams, there is no ‘THE EQUATION’ to solve for deflections on complex formations. To go around this, we can simply split the whole sheet into many nodes and lines. However, now that we are working in 2 dimensions, our elements can’t be a line. So, we can switch the elements into something like a triangle. Now, we can split our sheet into little triangular elements. Each has three little lines and three nodes. Just like how we started with beams, we must know the actual solution values somewhere in the design because it is fixed or restrained to something else. From there, we solve for each little line and each little element until we can solve for the whole model. Basically, we transformed the whole shell into many small one-dimensional beams. The collection of all the elements together is called Mesh. The more elements we have, the more accurate our results will be, but also the more calculations we will have to do. 3-Dimensional Solid Objects:At this point, we can jump into 3-Dimensional objects. which can be complex-looking turbines, gears, casings, consumer products, etc. We can refer to those as SOLIDS. As solids can take many different shapes and forms, there is no ‘THE EQUATION’ for all kinds of irregular shapes. However, that is not a problem because we can just split the whole thing into small elements to end up with a bunch of nodes and lines. Our element shape this time will have to be 3-dimensional shape, like a Tetrahedral, which is the shape of elements used in a software like SOLIDWORKS. As always, with one location of the design is known to us, so we can use THE EQUATION to solve what is happening in the next nodes, and move from there to the rest of the model. Generally speaking, the more elements we have, the more nodes and lines we have, the more accurate our results can be, and the more work we will have to do to solve it. Summary:In a nutshell, Finite Element Analysis is the idea of splitting any model into smaller elements that we can solve one at a time, then putting all those elements together can give us a good understanding of what is happening in the whole model. The power of FEA is that it enables us to understand and simulate how a specific design reacts to different conditions regardless of how complex the design is. Throughout this post, we gave a bit of focus to analyzing deflections. However, the same approach applies to analyzing and understanding many other parameters like stress distribution, the factor of safety distribution, etc. This post does not represent a factual background on Finite Element Analysis and should not be taken as such. Rather, you can take it as a way to simplify our understanding of what Finite Element Analysis is all about. If you are looking to dive into the use of an FEA-based simulation tool like SOLIDWORKS simulation, you can check out SOLIDWORKS Simulation Associate course. By Tayseer Almattar, TforDesign FounderTayseer is the founder of TforDesign. He has a passion for learning design and making all learning digestible and exciting.

LinkedIn: https://www.linkedin.com/in/tayseer-almattar-design-innovation

1 Comment

12/29/2021 05:59:04 am

I never knew that knowing a bit of background about FEA will help us understand many of the settings to optimize our results. I never thought that it would be like this, it is really a good article. Thank you for the information about fea services.

Reply

Leave a Reply. |

AuthorThe following blogs are written by TforDesign team and community members. Categories

All

|

© 2013 - 2024 TforDesign. All rights reserved.

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

Terms & Conditions | Privacy Policy | Cookie Policy | Sitemap

RSS Feed

RSS Feed